Turbojet, Turbofan, Turboprop

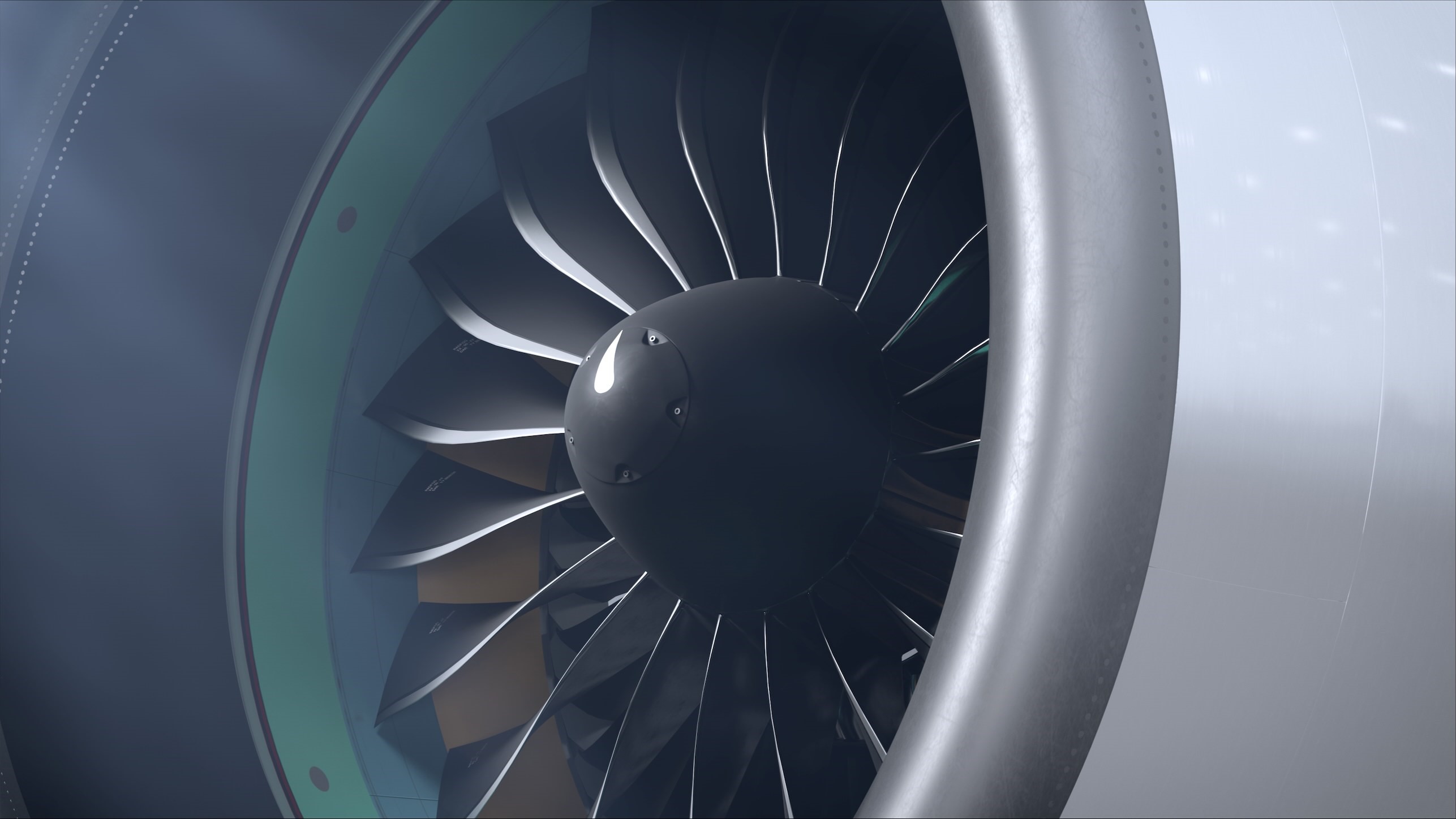

Most large commercial aircraft use turbofan engines while smaller regional carriers often use turboprop engines. Turbofans and turboprops are variations of the original turbojet engine, a gas turbine engine that produces thrust. A turbojet engine takes in air that is compressed and mixed with fuel. This mixture is burned in the combustor, which produces an extremely hot, expanding gas. As that gas is expelled, it powers a turbine that drives the compressor. The exhaust not used by the turbine passes through a propelling nozzle that creates thrust, the force needed to move an aircraft through the air. A turbofan engine basically adds an additional fan to the front of a traditional turbojet engine. This fan causes some of the air that is taken in by the engine to bypass the combustion chamber and turbines. The bypassed air is not heated by the core of the engine and is instead directly expelled from the nozzle. This results in a layer of cool air above and below the burnt fuel, which creates an insulating noise shield of sorts. Depending on how much air is bypassed from the engine, a turbofan is classified as either high-bypass or low-bypass. The majority of commercial jetliners use high-bypass turbofan engines. The easiest way to think of a turboprop engine is to picture a propeller attached to the standard turbojet engine explained above. Rather than powering the compressor as in a turbojet, the turbine shaft of a turboprop engine is connected to a propeller placed outside of the engine. Turboprop engines do not provide as much airspeed as turbofans, which is why they are primarily used by smaller regional carriers.