Delivering the cleanest cabin air in aviation history

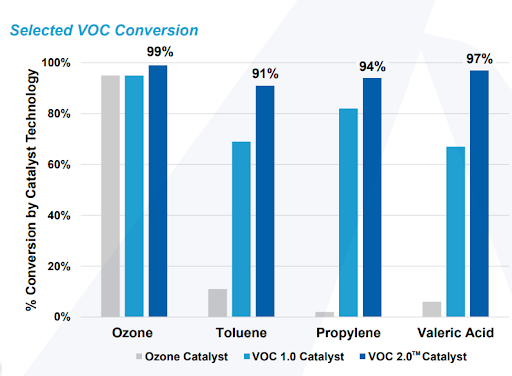

With 99% ozone capture rate, this converter dramatically improves on the 95% efficiency of previous models - eliminating harmful ozone more effectively than ever. The latest design also targets VOCs removal. For example:

Toluene removal jumps from 67% (VOC 1.0) to an impressive 91%, far outperforming competitors (typically around 11%)

Propylene and valeric acid capture rates have also seen major performance gains

The result: cleaner, safer, and more comfortable air for passengers and crew, making the BASF VOZC the most advanced cabin air solution available.